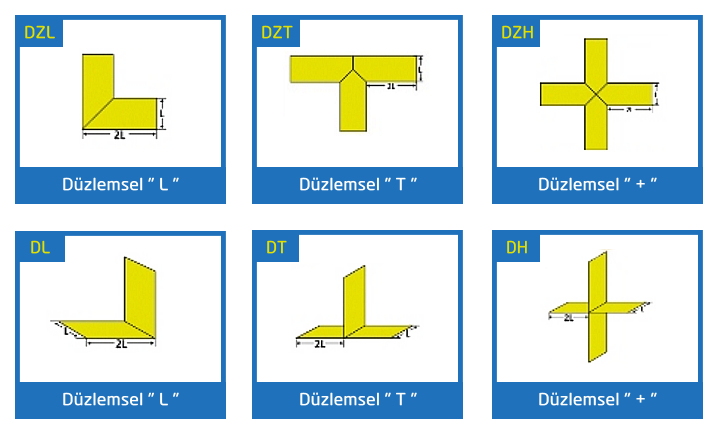

PVC Water Holder Tape, Jointing Parts

During the application of PVC Suction Tapes, especially at the joint intersection, welding should be done very well. Special joining pieces are used in the corners and for the attachment of different types of cooling bands. These joining parts are manufactured specially in the desired shapes as below or according to the places where the application will be made.

Special Productions with Connected Edges;

PVC sucker tapes are placed on the mold and they are manufactured upon request on both sides with 50 cm intervals on the edges to be fully connected to the reinforcement.

PVC Water Holder Tape, Quality Valuesleri

Our productions are TS 3078 certified. 23 ° C Laboratory quality values are as follows.

| Tensile Strength |

| Average % 140 kg/cm |

| Elongation Ratio |

| Average %225 minimum %200 |

| Hardness |

| Shore A 75 (± 5) |

| Unit Volume Mass |

| 1,27(+-0.04) gr/cm |

| Water Absorption Rate (Mass) |

| Maximum by weight %1.5 |

| Ash Amount |

| Maximum by weight %5 |

| Alkali Resistance |

| Fully Resistant |

| Heat Range |

| -35°C , +50°C |

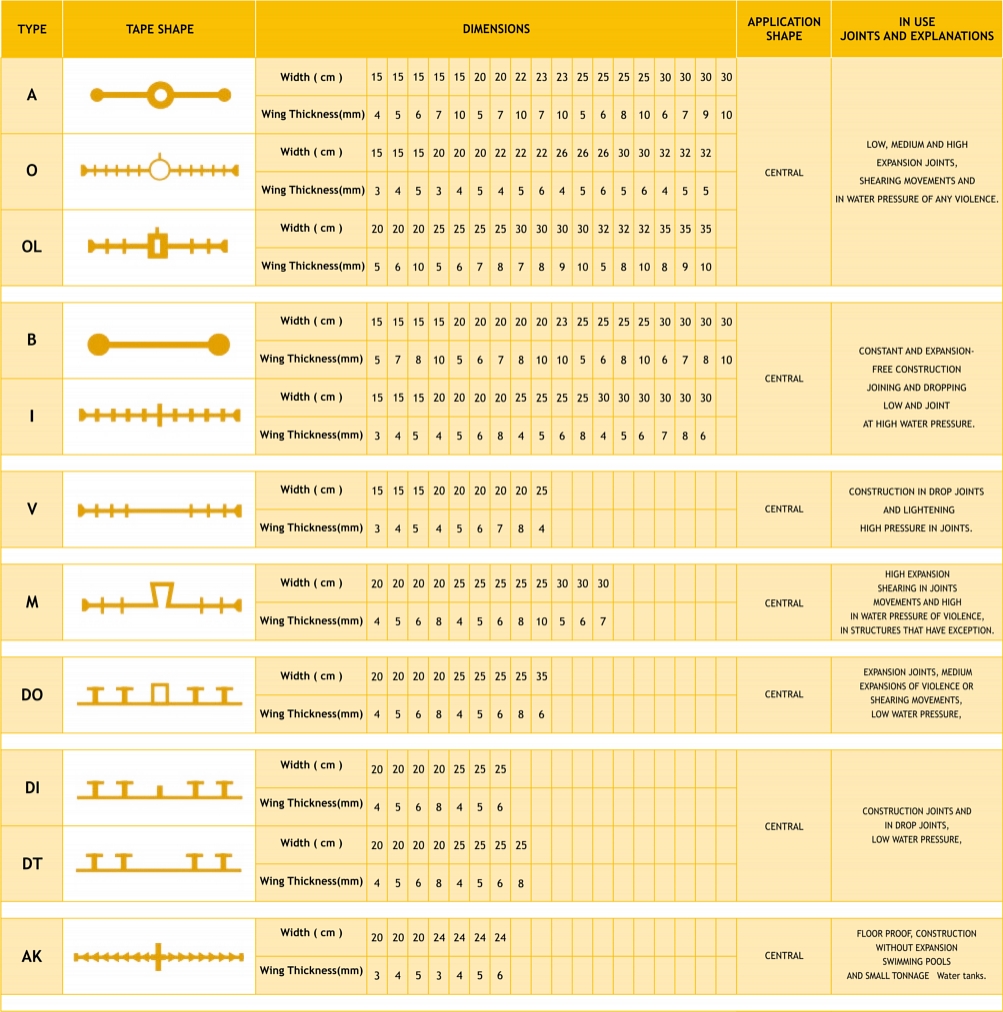

PVC Water Holder Tape, Type and Dimensions

PVC Water Holder, Size Determination

The following considerations should be taken into consideration when selecting the size of the type of the cooler.

- Concrete Construction

- Concrete Thickness

- Joint Width

- Expansion in the joint (size of the movements such as contraction, sitting)

- Water pressure height

In places where there is a high ground movement (especially earthquake risk), where the water pressure is high, where the movements such as expansion, contraction, carving in joints are high, the ones with the wall thicknesses of the absorber belts to be selected should be used.

| L < t | Should |

| L > 6a + d | Should |

| Y > L - d/2 | Should |

| X > 2a | Should |

| L |

Cross Section Length (mm) |

| t | Concrete Thickness |

| a | Largest agrega grain diameter |

| d | Joint Range |

| y | Distance to concrete surface (mm) |

| x | Distance to the closest equipment |

Table-B.

| Concrete Thickness (cm) T |

Tape Cross Section Length (mm) L |

Band Thickness (mm) a1 (min) |

| 20-40 | 150 | 3 |

| 35-50 | 200 | 4 |

| 40-60 | 250 | 4 |

| 50-70 | 300 | 4 |

| 60-80 | 350 | 4 |

| 80-100 | 400 | 6 |

| 100+ | 450 | 8 |

PVC Su Tutucu Bant Montaj

Joint face molds for pouring concrete must be 2-part and water-retaining tape should be placed between 2-part formwork. In order to ensure complete water tightness, it is necessary to ensure that there are no foreign materials such as dust, mortar pieces, etc. on the surfaces of the water retaining tape and that it is very well wound by the concrete. Concrete should be of suitable consistency and there should be no air gap and vibration should be done very well in these parts.

Welding Processes

PVC Water Holder Tapes are added together with hot welding (melting) system with cross-sectional surfaces. The necessary materials for this;

- Welding Blade: Wire made of copper or brass with minimum thickness of 5 mm suitable for heating with butane gas under the conditions of electricity, which can work thermostatically with electricity, Wire, Brush, Knife,

- Welding Pattern: Made of wood or aluminum according to the type of sinks.

-

Making Welding: The opposite ends of the water holding bands to be welded are cut with a knife properly. Both parts are placed in the welding mold. In this case, make sure that the front faces of both parts come into contact. After the welding plate is cleaned with wire brush, it is heated up to 150-170 ° C in thermostatic heaters. For welding with butane gas burner, it is heated up to about 200 ° C. The welding plate which comes to the appropriate temperature is placed between the face surfaces of the two bands. and the remaining ends of both parts in the mold are expected to melt. Melting should be well controlled visually and should not be burned. If more melting occurs, carbonization occurs. After the belt is sufficiently melted, the mold is opened and the blade is removed and the ends of the two tapes are pressed and pressed together. Allow the weld to cool down (20 minutes). The welding blade must be cleaned with a wire brush. When cooling is completed, the welding mold is removed. Visually and manually check whether the weld is smooth. Particular attention should be paid to avoid burns, if burned, the tape ends must be re-cut and the welding must be done again, otherwise water leakage may occur.

Note: Thermostat controlled welding machine and wooden molds are available from our factory upon your request.

PVC Water Holder Tape,Band Selection

PVC Water Holder, Usage areas:

- Treatment Plants

- Dams

- Industrial Buildings

- Ponds

- Hydro Electric and Thermal Power Plants

- Retaining Walls

- Transmission Tunnels

- Subway and Road Tunnels

- Wharfage

- Water Tanks

- Water Treatment Plants

- Irrigation Channels

- Viaducts

- Swimming Pools

- Flooring and Foundations

PVC Water Holder, Product Safety Data Sheet

2- First Aid Measures: Do not damage the product during the hand contact. During the welding process, gas mask should be used, the resulting gases should not be inhaled.

3- Fire Fighting Measures: Materials are difficult to ignite and do not carry flame. If material is exposed to fire during fire caused by external factors, water or other fire extinguishing apparatus is intervened.

4- Precautions Against Spills and Leaks: Since the materials are solid, there is no dissolution and no additional precautions are needed.

5- Handling and Storage: Handling: Please consult the project manager during use or see the catalog. Storage: It should be stored in closed places where it is not exposed to sunlight, rolls should be stacked up to 4 on top of each other and should not be contacted with oil and dust.

6- Exposure Limit - Personal Protection: Wear gloves during use and wear mask during welding.

7- Physical and Chemical Properties:

Appearance:

Yellow Color

Odor: Trace

Solubility in Water: None

Combustion Rating: 150 C˚

8- Stability / Reactivity: No additional information is required within the recommended storage and handling information.

9- Toxicity Information: Does not contain toxic substances.

10- Ecological Information: It does not cause any harm during the stay in the water and soil.

11- Disposal: Since plastics are recyclable, piece materials must be collected regularly and delivered to authorized waste collection agencies.

12- Information on Transport: No special precaution is required during transport.

13- Classification according to regulations: There is no regulation about plastic products, it is arranged for consumer information.